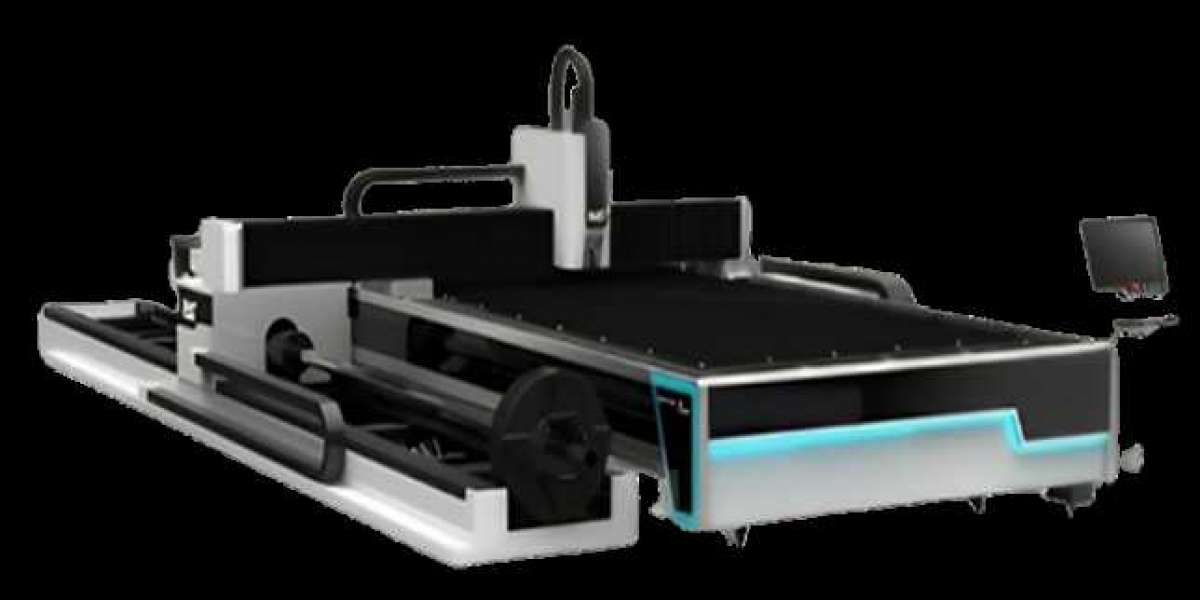

Advantages Of fiber Laser Cutting Machine

The powerful laser light released by a fiber laser cutting machine can easily cut through thick materials like steel. Fiber laser generators perform better than many other similar laser generators. These benefits have led to the widespread usage of fiber laser cutting machine in a variety of industries, including aviation and industrial. We will provide you with a thorough overview of the seven advantages of fiber laser cutting machine in this part.

Precision Cut

Higher power densities, better beam quality, and the ability to focus intensely are all advantages of fiber laser generators. Tight nesting of parts is made possible by the rapid, clean, and efficient production of components with tight tolerance and minimal kerfs made possible by the precision laser beam.

This is benefits for many industries, including electronics, where the beam operates at a very small scale without harming any components that are required to maximize yield and reduce material waste.

Versatility

Fiber laser cutting machine adaptability is one of its strengths; it allows for accurate, fine cuts in a range of materials, such as iron, carbon steel, stainless steel, and various reflecting materials. Its versatility in cutting a range of materials has led to its increasing use in creative fields including metalworking and sculpture.

High Speed And Efficiency

Another notable feature of fiber laser generators is their speed; when cutting straight lines with a thickness of 1mm, they may cut three times quicker than conventional laser generators. Compared to traditional sheet metal cutting machinery, fiber laser technology is quick and energy-efficient, enabling you to complete more work in less time.

Low Cost

The best option for cutting expenditures and operating expenses is a fiber laser generator. It is a financially sensible alternative, with very low maintenance costs and the highest outlay of any kind during the machine's lifetime being the purchase price. Installing a fiber laser generator would not only reduce energy consumption each time it is utilized, but it will also help hardware last longer because it uses less energy.

Easy To Operate

The equipment can be operated by an intelligent control system thanks to the laser cutting machine. Data is received by the computer-aided design workstation, which then configures the laser cutting material to create a desired pattern or design. Even someone with little expertise running a machine can do simple activities.

Ease Of Maintenance

While fiber laser cutting machine are long-lasting, require less adjustment and part replacement, and are less likely to break down, they demand less maintenance money. Nitrogen assistance is another tool that fiber laser generators can utilize to speed up and improve the accuracy of their cuts.

Customization

If the standard laser cutter not be able to fulfill your manufacturing requirements, you have the option to ask the manufacturer for customisation. Customized machines may better satisfy the flexibility of firm production, and the majority of highly qualified manufacturers in the sector offer customized services. One way to improve the machine's fit in your workplace and save time when changing materials is to modify the size of the machine table.

Disadvantages Of Fiber Laser Cutting Machine

Metal Thickness Limitation

When it comes to cutting really thick sheets, fiber laser cutting is not as effective as other thermal cutting techniques. The machine's power and level of competence determine the maximum thickness that can be cut. Metal fabrication businesses typically utilize lasers to cut metal that is between 15 and 30 mm thick.

Though the cutting speed for thicker metal is slower, the fiber laser cutting machine current power of up to 50kw allows it to partially cut through the limit of metal thickness.

Hazardous Gas Smoke

While many materials do not emit hazardous fumes during cutting, many polymers and some metals react to produce fumes and dangerous fumes. For example, polytetrafluoroethylene and various fluoropolymers generate phosgene when heated to high temperatures. Poor ventilation can cause operator discomfort and damage the machine itself, so a good ventilation system is a must for a safe working environment.

Professional Knowledge Required

A skilled machine operator is necessary for a laser cutting machine to reach its maximum potential. The cut quality of the metal will be as predicted if the cutting parameters are adjusted properly.

Purchase Cost

It's likely that purchasing a fiber laser cutting machine will require a substantial financial outlay. Purchasing a fiber laser cutting can be twice as expensive as purchasing a waterjet or plasma cutter. Long-term savings on operating expenses and reduced inefficiencies more than offset the purchase price.

Partial Material Evaporates

A significant disadvantage of fiber laser cutting machine is evaporation, which usually happens while cutting materials like plastics. Although a skilled machine operator may easily overcome this flaw, preventing this issue can be highly expensive.

For more information on the benefits of using laser cutting for your parts, contact Supreme Technologies.